The Difference Between Planetary and Rotary Concrete Floor Grinders | Xtreme Polishing Systems

What Exactly Are Planetary Grinders And Traditional Rotary Grinders?

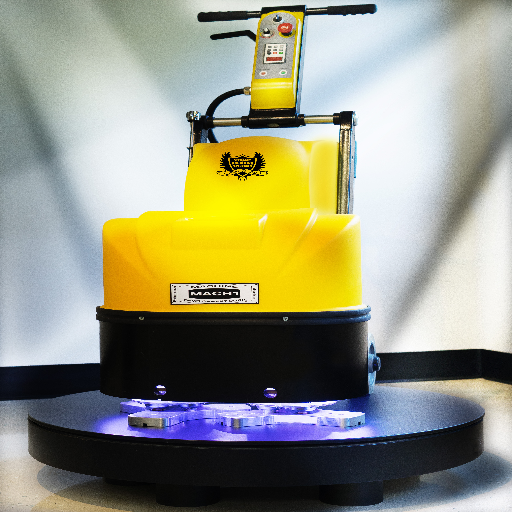

There are two major types of concrete floor grinders to adequately prepare a concrete floor. These robust pieces of equipment are used to smooth, level, prepare, polish, and remove thick coatings on concrete surfaces. Since concrete is an economical flooring option it has become increasingly popular among warehouses, commercial businesses, retail, schools, residential and other facilities. Concrete floor grinders are essential pieces of equipment that will aid in completing concrete floors. Understanding the differences between rotary floor grinders and planetary floor grinders will assist you in choosing the proper equipment for the specific project.

Traditional rotary grinders are heavyweight which helps speed up the process and there is no need for belts or pulleys when using this type of floor grinder. A skilled operator is recommended to properly operate these heavyweight pieces of machinery. Planetary floor grinders are flexible and lightweight so they are easier to maneuver and designed to move in a straight line across the concrete. Planetary floor grinders are ideal to use for lighter projects.

Resources, Guidance and Support

Concrete all around the world has long dominated industries, particularly flooring, because of its exceptional durability, low maintenance and simply pleasant appearance that it delivers. Xtreme Polishing Systems supplies the industry with innovative and professional concrete polishing and decorative concrete products , equipment , chemicals and so much more. Our professionals are specially trained with our products and will deliver the fundamental guidance and customer service when preparing and executing a concrete floor.

The experts at Xtreme Polishing Systems understand that every surface can variate in properties, therefore each slab must be treated differently. We’re here to guide you in the proper direction, so please call us at (877) 958-5732 with any questions regarding ‘ The Difference Between Planetary and Rotary Floor Grinders ‘ or visit our website and browse our products today. Whether you’re a new business owner, flooring subcontractor, DIYer, craftsmen, artist, existing business or homeowner, our exquisite product selection and extensive industry experience will assist you every step of the way, from start to finish.